Cremer product unscramblers (PU) use multiple cascading vibratory plates and a conveyor belt for the separation and singulation of jumbled and clustered products. Suitable for all kinds of products... Read more >

Home > Industrial >

Product unscramblers

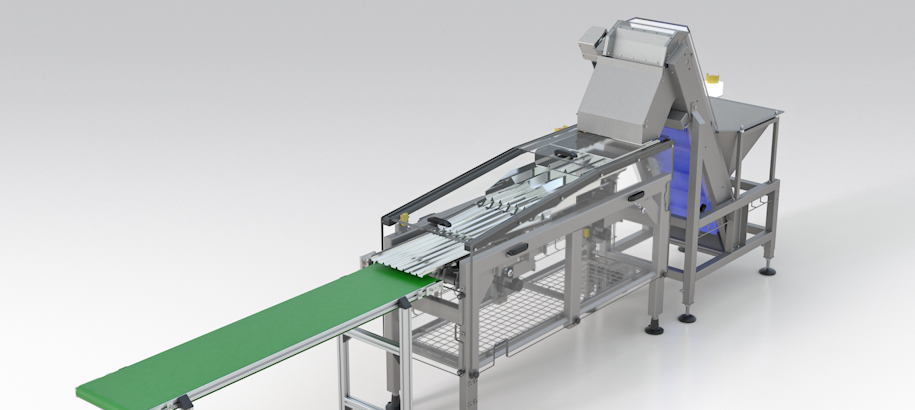

Cremer product unscramblers (PU) use multiple cascading vibratory plates and a conveyor belt for the separation and singulation of jumbled and clustered products. Suitable for all kinds of products for a wide range of applications and industries. The product unscrambler can be used as a stand-alone machine, but can also be integrated into larger automated packaging lines. Cremer’s product unscramblers deliver a comprehensive package of efficiency, adaptability, and user-friendliness to enhance your production processes.

The importance of separation for pick and place systems

Pick-and-place robots are being increasingly used in various industries. When these robots are used in assembly, inspection or packaging operations, they seamlessly pick products or workpieces off an incoming conveyor belt and then transfer them to another conveyor system or directly into any case or package.

The robots’ vision system accurately scans each individual product to be retrieved. This underlines how important it is to ensure that the products on the incoming conveyor are separately presented. Not only must they be sufficiently singulated, but preferably also oriented in the right direction to ensure smooth and error-free processing.

Configuration

The bulk product is first loaded into a hopper or collector chute with a dosing conveyor that transports the clustered products in smaller portions to the vibratory section. The shape and style of the vibration plates are product specific designed to ensure that the product can be singulated as effectively as possible. The singulated and correctly oriented products are presented on an optional outfeed conveyor from which a pick and place robot can grab each product. Depending on the required output – often determined by the number of pick and place robots or their picking speed – the number of product lanes can vary from 4 to 16.

The product unscramblers are designed with minimal changeover parts and can be disassembled without tools, simplifying maintenance and reducing downtime. Plus, they operate with low noise emission, creating a quieter and more comfortable working environment.

Applications

Unscrambling, product singulation and orienting are the three basic requirements for all pick and place systems. The mechanical concept of Cremer unscramblers has been applied and proven to be very efficient for many applications, such as:

- Automotive industry (hardware)

- Medical devices (syringes, lancets, etc.)

- Stick packs (sugar, coffee, etc.)

- Confectionery and biscuits

- All sorts of sachets and pouches

Solutions beyond counting

Cremer does not only single out products to count them by piece – we offer comprehensive solutions that go beyond counting! Our daily mission is to ensure that companies can count and package their products in a 100% accurate, fast and profitable way. Our core strengths lie in technology and innovation, and they serve as the cornerstone for our global market presence. We strive to develop top solutions that inspire the market and allow us to remain at the forefront of technology. Our customers range from small family enterprises and mid-sized production facilities to leading multinational corporations worldwide.

Technical data

| Number of vibratory plates | 4 or 6 |

|---|---|

| Number of product lanes | 4, 6, 8, 12 or 16 |

| Nominal frame size | 400 mm, 600 mm or 800 mm |

| Frame execution | Stainless steel or painted steel |

Downloads