The CFS bottle filling machine for solid dose products can accommodate up to four counting modules, depending on the required output. The scalable performance combined with a small footprint... Read more >

Home > Pharmaceutical >

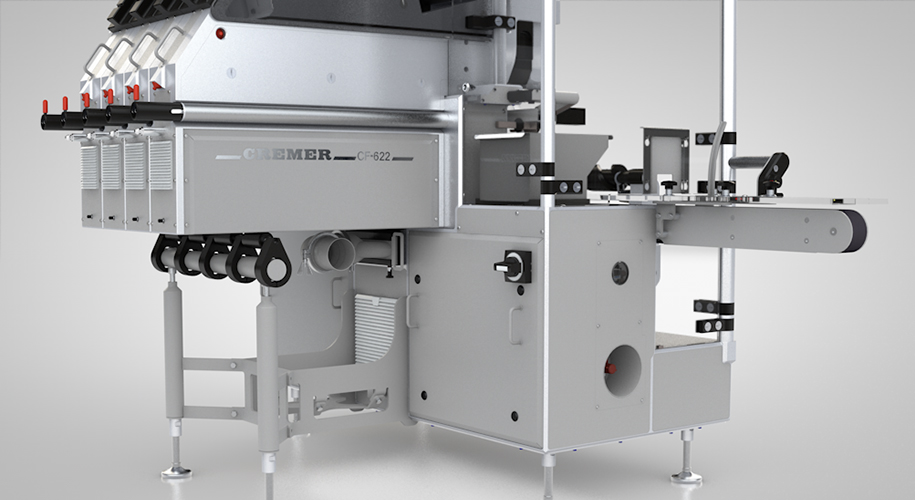

CFS series

- 100% counting accuracy

- Fills up to 200 bottles per minute

- Easy to operate

- Small footprint

- Many optional features for increased output and performance optimisation

The CFS bottle filling machine for solid dose products can accommodate up to four counting modules, depending on the required output. The scalable performance combined with a small footprint makes this counting and filling machine the most versatile on the market. Its GMP-compliant design allows good accessibility, cleanability and guarantees complete operating safety.

Accurate, reliable and flexible modular solution

With only a few change parts the CFS filling machine is able to count almost any kind of pill, tablet, and hard or softgel capsule in bulk quantities or single piece discharges in almost any kind of plastic or glass bottle: round, oval and rectangular. Due to its small footprint, the autonomous bottle filling machine for tablets and capsules can be easily integrated into complete bottle filling and packaging lines. These key features have made them find their way too many of world’s largest companies in the pharmaceutical and nutraceutical industry.

Optimize production efficiency

The tablet and capsule counting module with 6 channels do not require any format parts, are very easy to clean and free of calibration and extensive maintenance. All product contact parts are constructed from pharmaceutical-grade materials and are suitable for autoclave cleaning. For added convenience, an optional cleaning trolley is available for efficient cleaning and storage of the product contact parts.

Additionally, the slim design of the modules allows for flexible placement of varying numbers of counting modules within the CFS 622, all while maintaining a small footprint. The CFS counting and filling machine can be supplied as a standard product counting machine or be designed for custom applications. Depending on the type of product and counting modules the CFS 622 fills up to 200 bottles per minute.

Custom pharmaceutical solutions

Reliable, resourceful and innovative are the key values that have made Cremer a market leader in counting and filling machines. Our market strength lies in the ability to provide both standardised as well as fully customisable solutions for both the pharmaceutical and nutraceutical industries.

By combining advanced engineering with a dedicated emphasis on performance and durability, we have developed a range of pharmaceutical filling machines that encompasses compact tablet counters, modular high-end counters, and bottle fillers with unprecedented performance.

The CFS 622 offers many standard benefits such as:

• Large central bulk hopper with smart dosing slider

• Servo driven vibratory plates for optimal product separation

• Servo driven separation and discharge flaps

• High repeatability

• Central dust collection manifold

• Intuitive HMI control

Elevate quality standards with single tablet reject

Experience unrivaled product quality and elevate your production standards with our advanced BottleChrom inspection system with Single Tablet Reject function. This advanced product inspection system enables the detection and removal of defective or incorrect tablets and capsules, ensuring that every bottle contains only products of the highest quality. The main advantage of the state-of-the-art vibratory plate inspection system is that incorrect or damaged tablets or capsules, are removed almost instantly and on-the-fly, without affecting the overall machine output. This provides you the confidence to deliver exceptional products that meet the highest pharmaceutical industry standards.

Video of the CFS 622 with BottleChrom camera inspection and Single Tablet Reject

Technical data

| Counting module positions | 1-4 |

|---|---|

| Max. output | 200 bottles/min.* |

| Bottle height | 35-200 mm** |

| Bottle diameter | 20-125 mm |

| Bottle shape | Round, oval, square, rectangular |

| Solids type | Tablets (coated and uncoated), capsules, gelcaps |

| Solids length | 3-30mm |

| Solids diameter | 3-20 mm |

| * Related to the product and number of modules | |

| ** Higher bottles are possible on special request. |