The versatility of the Washdown counting machine extends to the possibility of counting a large variety of different food products either in bulk quantities or for consumer-sized packages. The... Read more >

Home > Industrial >

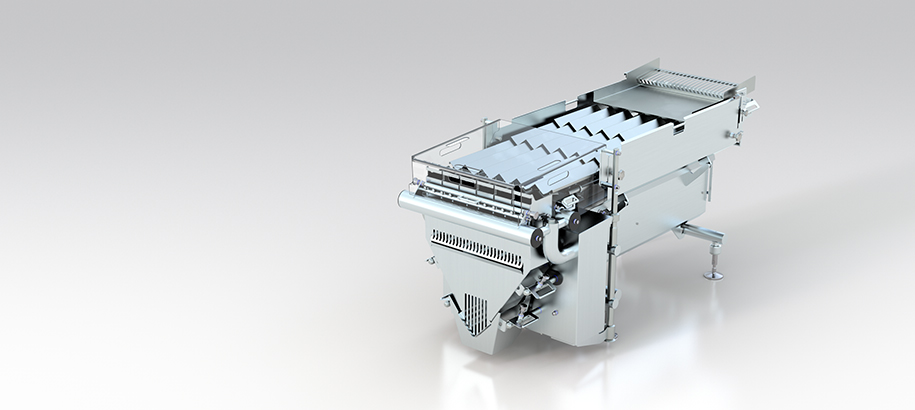

Washdown

- More efficient than weighing

- Small footprint

- Scalable output and performance

- Also suitable for chilled and deep-frozen food (IQF)

- Separate parts trolley for convenient sanitizing

The versatility of the Washdown counting machine extends to the possibility of counting a large variety of different food products either in bulk quantities or for consumer-sized packages. The food product counting machine is very suitable for use in hygienic environments due to its washdown design.

The compact counting machine has a relatively small footprint and can easily be placed on a hygienic platform, on top of a VFFS bagmaker or over an indexing tray or carton conveyor. Cremer can also offer a total and fully customised counting and packaging solution that is perfectly suited to your needs. We deliver solutions that go beyond counting. Our daily effort is to ensure that companies can count and package their products in a 100% accurate, fast and profitable way.

Food safety

The washdown design and execution makes the WD counting machine ideal for harsh working environments, such as meat, poultry and marine food processing. The counting machine is designed and built in accordance with Sanitary Equipment Design Principles. This means that all contact surfaces of the equipment must be accessible for effective and efficient cleaning and sanitizing. The stainless steel frame of the counting machine and the corrosion-resistant contact parts can be cleaned with a low-pressure hose wash and moderate use of sanitizing chemicals.

The food contact parts are FDA-compliant for processing both food and non-food products. They can be swiftly removed from the machine without the use of any tools. This makes it easy to keep the machine clean and change the food contact parts quickly without the risk of cross-pollination. A cleaning trolley can be used for convenient storage and cleaning of all food contact parts.

Counting food process

It has been proven that counting food products by piece is more efficient than counting by weight. With optical counting, accuracy is not affected by small weight variations between individual products. Cremer counting machines have vibratory plates for product transport and separation. Optional with the Washdown series is a vibrating sieve with a collector tray to catch crumbs and scraps. At the end of the vibratory plates is a product detection unit that counts every product that falls down. Separation flaps serve as a buffer to separate the count between discharges.

Applications such as:

- Frozen meat, like meatballs and sausages

- Chicken drums

- Sea food, like shrimps & prawns, IQF fish filets

- Cheese parts

- Bakery products

- Donuts

- IQF Egg rolls

Video of the WD product counting machine

Technical data

| Model | WD 6100 |

|---|---|

| Number of counting channels | 6 |

| Size of the WD 6100 (L x W) | 2000mm x 850mm |

| Output | Up to 45 discharges/minute* |

| *Related to product size and desired count |

Downloads