Reliable, resourceful and innovative are the primary values that have made Cremer a market leader in solid dose tablet bottle filling machines for the pharmaceutical industry. Advanced engineering with a committed focus on performance and durability resulted in a series of bottle filling systems that ranges from compact tablet and capsules counters to modular based high-end counting and in-motion tablet bottle filling machines with unprecedented output and efficiency.

Over 40 years of experience in the pharmaceutical market allowed Cremer to pace with the needs of an increasingly demanding market. Our tablet bottle filling machines has proven its durability and reliability with hundreds of them in use worldwide. For Cremer, being part of the Uhlmann Group is not just another strategic leap forward: it allows us to anticipate future market requirements by sharing technical expertise and market insights. With the pharmaceutical tablet bottle filling machines has Cremer defined a high standard for counting.

Our market strength lies in our ability to provide both standardised as well as fully customisable counting and packaging solutions, like tablet counting and filling machines, for both the pharmaceutical and nutraceutical industry. We also understand the impact of downtime costs on our customers, which is why our tablet counting and filling machines must be able to run 24/7 with very limited changeover and cleaning time. This is why our counting machines have features that facilitate the cleaning of the counting machine.

And thanks to our turnkey solutions, customers no longer have to think about planning because we offer them a solution for the entire production line from A to Z.

- 100% guaranteed counting accuracy

- Modular-based design for scalable performance

- Fast and tool-free change-over with minimum format parts

Pharmaceutical counting and bottle filling solutions

CFS series

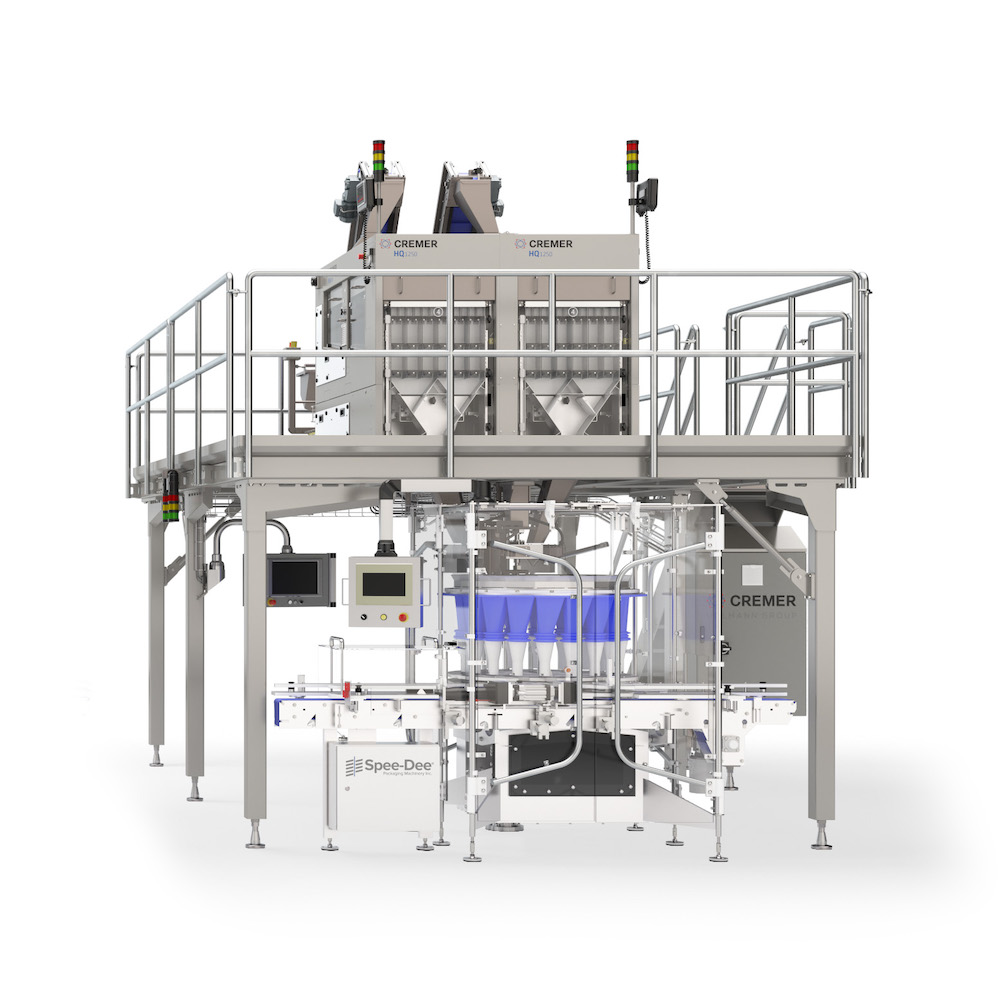

The next generation bottle filling system for solid dose products. Fills up to 200 bottles per minute.The CFS is the ultimate answer to the increasing demand for flexible, modular solutions, increased productivity, efficiency and a smaller footprint.

CF 1220

The number one mid-range counting and bottle filling solution for solid dose products. Fills up to 55 bottles per minute.Extremely versatile and reliable tablet and capsule counting and bottle filling system for the pharmaceutical, nutraceutical and generic drug industry.

IBC 50

The perfect choise for cost-effective entry into bottle packaging automation.Integrated bottling center. Small-batch bottling operations on a compact footprint for increased productivity and efficiency.

Recent articles

About our cases, industries and products.