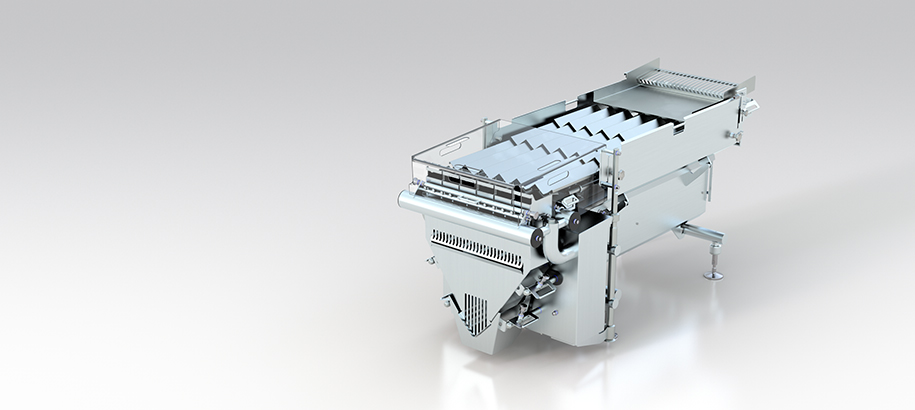

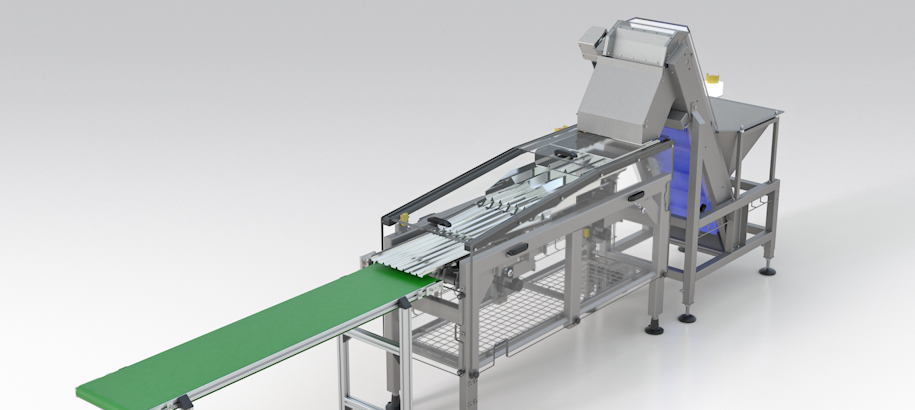

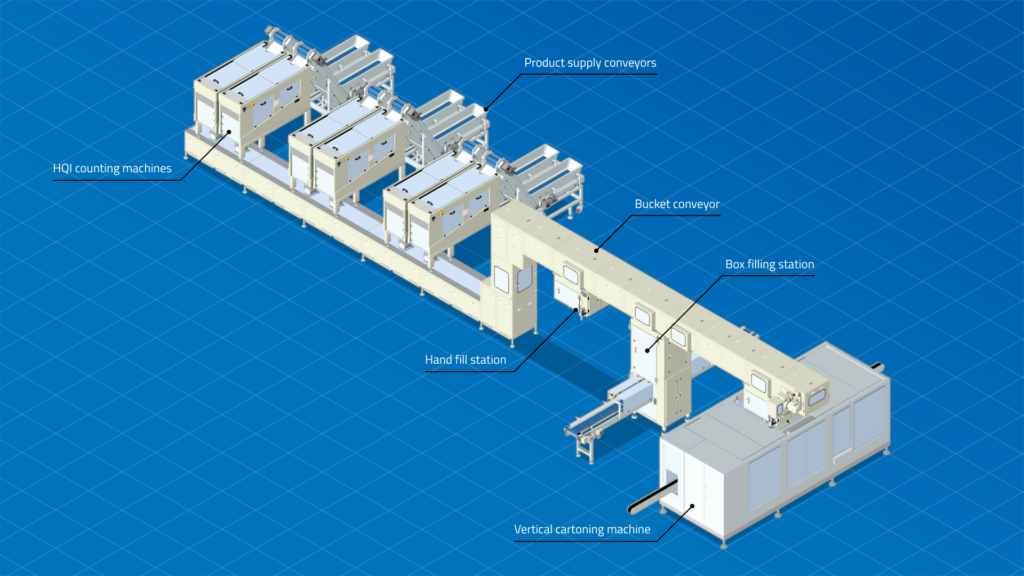

Whenever products vary in weight or when they are difficult to separate; counting by the piece makes more sense than industrial weighing machines or using pick-and-place robots. When the secondary package contains an assorted mix of different products or flavours, the most sensible packing solution would be product counting. An industrial piece counting machine guarantees 100% accuracy and leads to satisfied consumers and increasing Return of Investment (ROI) through significantly reduced product waste.

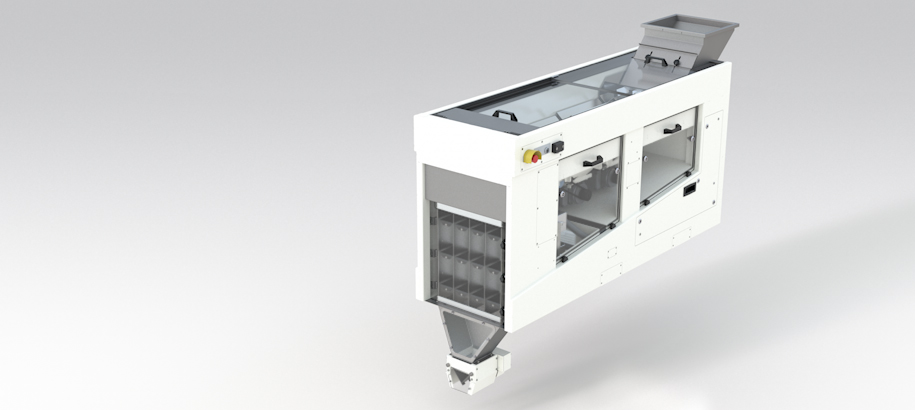

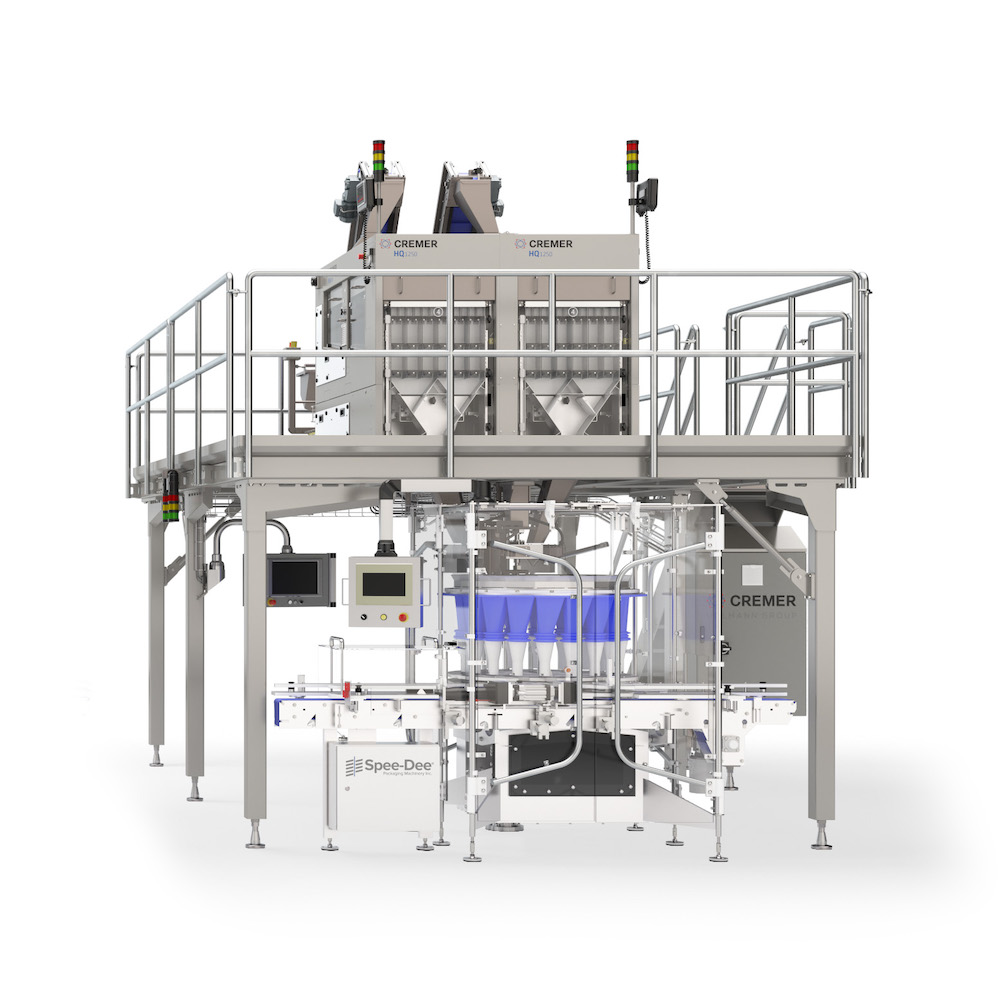

With more than seven decades of experience, Cremer is the world leading manufacturer of standard as well as customised counting and packaging solutions with unparalleled precision and performance. Cremer food counting machines are now used by many suppliers of food like twist-wrapped chocolates, sweets and chewing gums, beverage capsules and frozen snack foods etc.. But the industrial piece counting machine is also used for consumer goods like soap and detergent pouches, sweets, bakery products, hardware parts, medical devices, etc.

Cremer treats all its customers equally. For us, there is no difference between large multinationals with leading brands or small family businesses. Whenever product counting has proved to be the best way to pack your product over weighing, we are fully committed to developing a counting and packaging machine that is tailored to your needs and budget, considering that ROI is always a decisive factor for any company.

Any questions about industrial counting machines and packaging solutions? We would be more than happy to answer them for you. Please complete the online contact form below and we’ll get back to you as soon as possible.